Manufacturer of Cooling Tower, FRP Cooling Tower and Spare Parts

Ahmedabad-382445, Gujarat (India)

Round Bottle Type Cooling Tower

Design Specifications

The "ADVA-TECH" FRP round bottle type and square type cooling towers operate on the counterflow principle which gives the best performances. The air flow through the tower i nfi II is opposed to the water flow. The cold air meets the cooled water at the bottom ofthe infill providing maximum evaporation and heat transfer inthe infill.

Casing & Basin

The tower casing is made of though fiberglass reinforced plastic (FRP) and has sufficient structural strength to withstand high wind velocities and vibrations the portion of casing housing. The water collection sump, also of FRP, is leak - proof and avoids water spillage.

Fills

The fill is of rigid PVC and is of honeycomb design with large contact area. The fills splits the air and water into several streams, increasing the time of contact and also heat transfer between water and air. We can supply HIPS and ABS material fills for high temperature applications.

Water Distribution System

The water distribution system is fixed type and it is made of GI pipes with multiple branches and plastic spray nozzles. It is designed forvery low pressure drop and uniform distribution of water overfill area. We can supply automatic rotary sprin kler system for round bottle type cooling towers.

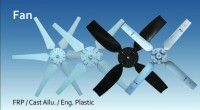

Fan

Specially designed energy efficient axial typefans with adjustable pitch, made of cast aluminium alloy or FRP. It is specially designed for low running cost and low noise level.

Electric Motor

Totally enclosed TENC type flanged mounted motor, with extended threaded shaft and having IP-55 degree of protection and are specially designed for cooling tower application.

Supporting Structure

All supporting steel members are hot-dip galvanized to minimize rusting and corrosion ensuring long service life even in corrosive atmosphere.

Square Type Cooling Tower

Design Specifications

The "ADVA-TECH" FRP round bottle type and square type cooling towers operate on the counterflow principle which gives the best performances. The air flow through the tower i nfi II is opposed to the water flow. The cold air meets the cooled water at the bottom ofthe infill providing maximum evaporation and heat transfer inthe infill.

Casing & Basin

The tower casing is made of though fiberglass reinforced plastic (FRP) and has sufficient structural strength to withstand high wind velocities and vibrations the portion of casing housing. The water collection sump, also of FRP, is leak - proof and avoids water spillage.

Fills

The fill is of rigid PVC and is of honeycomb design with large contact area. The fills splits the air and water into several streams, increasing the time of contact and also heat transfer between water and air. We can supply HIPS and ABS material fills for high temperature applications.

Water Distribution System

The water distribution system is fixed type and it is made of GI pipes with multiple branches and plastic spray nozzles. It is designed forvery low pressure drop and uniform distribution of water overfill area. We can supply automatic rotary sprin kler system for round bottle type cooling towers.

Fan

Specially designed energy efficient axial typefans with adjustable pitch, made of cast aluminium alloy or FRP. It is specially designed for low running cost and low noise level.

Electric Motor

Totally enclosed TENC type flanged mounted motor, with extended threaded shaft and having IP-55 degree of protection and are specially designed for cooling tower application.

Supporting Structure

All supporting steel members are hot-dip galvanized to minimize rusting and corrosion ensuring long service life even in corrosive atmosphere.

Single Flow Cross Flow Cooling Tower

Backed with a strong background of research, design and commitment to quality, our company offers well tested range of FRP Cross FlowType Cooling Towers. These cooling towers are manufactured using quality material like FRP, PVC, MS HDG and stainless steel supporting structure. Readily adaptable for any types of water cooling applications, these cooling towers are specially designed hard water, ceramic industries, steel industries, oil refineries and dusty atmosphere, our offered FRP Cross Flow Type CoolingTower is highlyacclaimed byclientsfor its chemical &corrosion resistance, maximum service life and high performance.

Design Specifications

ADVA-TECH cross flow cooling tower operates according to cross flow principle. The hot water is fed into a FRP splash box, having target nozzles in the bottom to equally distribute water over PVC perforated V- bar fill. By evaporation and direct contact the water transfers heat to the air, which is sucked in by propeller type fan?The cold water is collected in a basin at the bottom ofthe tower for re-circulation.

Casing

Casting is made oftough FRP panels and has sufficient structu ral strength to withstand high wind velocities and vibrations.

Fills & Drift Eliminator

PVC Perforated V Bar type fill is supplied, to provide maximum wetted surface, longer air water contact and more efficient water cooling. Drift Eliminators are made of PVC and positioned between fill and fan cylinder.

Water Distribution System

Hot water distribution splash box is open gravity type, will be made of FRP with HDPE gravity target nozzles.

Basin It is generally a RCC basin and is to be designed and constructed by the client, in accordance with out drawing.

Fan

The fan is of aero dynamic design, directly driven propeller type. It is made of adjustable Cast Aluminum blades and hub. The fan is statically and dynamically balanced.

Electric Motor

Special totally enclosed flange mounted motors, with extended shaft and sealed top is supplied with cooling tower. The motor is having totally weather proof IP-55 degree of protection, suitable for hot and humid atmosphere and it is covered by FRP motor cover.

Double Flow Cross Flow Cooling Tower

Backed with a strong background of research, design and commitment to quality, our company offers well tested range of FRP Cross FlowType Cooling Towers. These cooling towers are manufactured using quality material like FRP, PVC, MS HDG and stainless steel supporting structure. Readily adaptable for any types of water cooling applications, these cooling towers are specially designed hard water, ceramic industries, steel industries, oil refineries and dusty atmosphere, our offered FRP Cross Flow Type CoolingTower is highlyacclaimed byclientsfor its chemical &corrosion resistance, maximum service life and high performance.

Design Specifications

ADVA-TECH cross flow cooling tower operates according to cross flow principle. The hot water is fed into a FRP splash box, having target nozzles in the bottom to equally distribute water over PVC perforated V- bar fill. By evaporation and direct contact the water transfers heat to the air, which is sucked in by propeller type fan?The cold water is collected in a basin at the bottom ofthe tower for re-circulation.

Casing

Casting is made oftough FRP panels and has sufficient structu ral strength to withstand high wind velocities and vibrations.

Fills & Drift Eliminator

PVC Perforated V Bar type fill is supplied, to provide maximum wetted surface, longer air water contact and more efficient water cooling. Drift Eliminators are made of PVC and positioned between fill and fan cylinder.

Water Distribution System

Hot water distribution splash box is open gravity type, will be made of FRP with HDPE gravity target nozzles.

Basin It is generally a RCC basin and is to be designed and constructed by the client, in accordance with out drawing.

Fan

The fan is of aero dynamic design, directly driven propeller type. It is made of adjustable Cast Aluminum blades and hub. The fan is statically and dynamically balanced.

Electric Motor

Special totally enclosed flange mounted motors, with extended shaft and sealed top is supplied with cooling tower. The motor is having totally weather proof IP-55 degree of protection, suitable for hot and humid atmosphere and it is covered by FRP motor cover.

Natural Draft Cooling Tower

We hold expertise in manufacturing and supplying Natural Drafts Type Cooling Tower that are known for durability, corrosion resistance and reliability. These products are fabricated by strictly following the international quality standards. We ensure our customers are completely satisfied with our product range. Our quality testing unit has all the necessary tools to check the quality of the products on various parameters and under different conditions.

Pvc Fills For Cooling Tower

A wide range of edge folded PVC fill products to meet specific applications. Our standard fill products meet the requirements used in counterflow cooling towers. Our fills are with both edges folded and achieve high surface area for given volume.

PVC Fills are made by continuous forming and offer minimum resistance to airflow, providing more cooling by lower power consumption. They have uniform thickness throughout. Durable folded edges provide strength at critical locations on the fill.

PVC Perforated V Bar And Strip

We supply PVC Perforated V Bar and strip in the size of 4', 6' and 8' long for Cross Flow coolingTowers.

Nozzles For Cooling Tower

We have all type of nozzles for all designed cooling towers. We are supplying heavy dutyJet Spray type nozzles in the size of 1/2", Va" and 1" in Nylon-6 and HDPE material. We also supplying Deck Spray type nozzles in the size of 11/2"to 3" inABS and PP material.

Sprinkler For Cooling Tower

Rotary sprinkler is available in the size of 2" to 6" size, made from cast alluminium alloy, Stainless Steel and PVC material.

We also supply sprinkler parts like PVC branch pipe, Tension Bar, Turn Buckle, PVC and FRP Eliminator, Pipe clamp, End cap, etc.

Energy Efficient Fan Assembly

It is Aerodynamically designed to give maximum fan efficiency and a long life when handling saturated air at high velocity. Fan is of the adjustable multi blade design.The fan is balanced statically and dynamically to make it completely vibration and noise free. The fan is direct driven by motor, eliminating maintenance problems of V Belt / Gear drive mechanism.

We are supplying Fan Assembly in various materials like FRP, Alluminium and Engineering Plastic as per customer's requirement.

Fan Motor

Special type totally enclosed flange mounted motors, with extended threaded shaft and sealed top is supplied with cooling tower. The motor is having totally weather proof IP-55 degree of protection, suitable for hot and humid atmosphere. Motor HP will be determined by the calculated thermal requirements.